Aluminium and steel extrusion applications

trending_up Automotive Extrusion Parts

Aluminium and steel extrusion parts for automotive applications

- Automobile gearbox

- Accumulator' s housing

- Output shaft

- Transmission shaft

- Universal joint

- Engine end drive sleeve

- Rear axle and sleeve

- Input axle hub

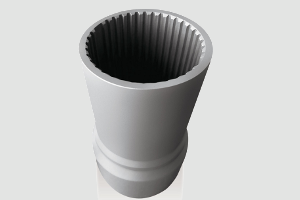

- Aluminum alloy spline sleeve

- Face tooth

- Break system parts

- parts for chassis

- extrusion parts for seat systems

trending_upImpact Extrusion Parts

Impact extrusion and cold forging applications

- Spline sheath cold extruded part

- Bolts and special screws

- axle sleeves

- Hexagon flange

- Flat flange

- Series pistons

- Spline bushing

- Interior parts

- Flat parts

- Welded parts

trending_up Other Extrusion Parts

Transmission systems and aluminium profiles

- Stators

- Electronic unit pump

- fasteners and claps

- BQT4A Top cylinder

- YB2L Top cylinder

- CRP Top cylinder

- High pressure common rail plunger sleeve

- High pressure common rail injector body

- Electronically controlled unit pump plunger

Cold extrusion punchers

Cold impact extrusion and cold forged technology fields

Cold extrusion - general information - machine equipment - technical information

The production is based on international and Chinese advanced cold and warm forging production equipment.

A full-automatic precision parts production line, with more than 70 160t-2000t mechanical metal forming machines, hydraulic metal forming machines, high-speed multi station special parts forming machines, more than 30 sets of heat treatment and inspection equipment, excellent production capacity are available .

The company extends over 73000 square meters of modern standard factory buildings.

The company has established a perfect ISO / TS16949 quality assurance system and adopted advanced 6S management mode on site.

A complete set of international leading product testing equipment for product testing operation and analysis functions is established.

The measurement equipment consists of Three coordinate measuring system (Hexagon)、Profile roughness、2.5Dprojector、component spectrum analyzer(Oxford).

The main testing devices are Rockwell hardness tester, Brinell hardness tester, metallographic microscope, polishing machine, inlay machine, cutting machine, digital projector.

The quality is ensured by a strict monitoring system.

CNC automatic cleaning line

Automated follow-up operations to extrusions

Head Treatment Center

Head treatment center of cold extrusion workshop

Common aspects of cold extrusion applications mainly used in automotive industry

Extrusion is a process in which a coil of raw material is cut accurately and pressed or pulled through or into a shaping tool with high speed and precision.

The material is deformed below an elastic limit and retains this shape after leaving the tool

The extrusion processes differ. The material is either pulled forward into a die or pressed or pushed back into the die, whereby the material can also deform in the transverse direction.

In this way a net shape or near net shape prozess generates quality finished surfaces, with less final CNC manufacturing requirements.

Since the production of the necessary tools for extrusion processes is very complex, economical production is only possible with annual quantities greater than 100,000 parts.

Raw material is saved and the scrap of material is less.

Mechanical properties of the raw material can be improved.

Extrusion processes can be carried out on the basis of different materials. (carbon steels, Aluminium, Copper, Brass, Stainless steel, Nickel Alloys, Alloy steels)